- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

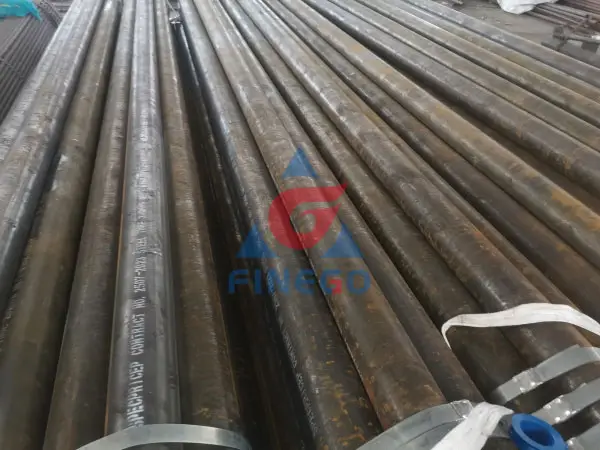

Seamless Steel Pipe

ASTM A335 Steel Tube

ASTM A335 is a seamless ferritic alloy-steel pipe used for high-temperature applications.

Diameter: 16-1016mm

Thickness: 2---120mm

Steel Grade: p1 p2 p5 p9 p11 p12 p22

Surface: Oiled, black painted to prevent rust

Application Fileds: The most common use of grades P11, P22, and P91 is in the power industry and petro-chemical plants, Grades P5 and P9 are commonly used in refineries.

Standard

Specification

ASTM A335 Alloy Steel Seamless Pipes are Carbon Steel Pipes with subsequent addition of chromium, molybdenum and sometimes vanadium are known as chrome moly Pipes. Molybdenum increases the strength of steel as well as the elastic limit, resistance to wear, impact qualities, and hardenability. Moly increases the resistance to softening, restrains grain growth and makes chromium steel less susceptible to embrittlement. Moly is the most effective single additive that increases high temperature creep strength. ASME Specification alloy steel Pipes are used for high temperature service applications. Seamless Alloy Steel Pipes according to ASTM A335 Grade P2 are reheated and furnished in full annlealed,isothermal annealed or normalised quenched and tempered condition. ASTM A335 Grade P2 Alloy Steel Seamless Pipes have a typical chemistry with additions of 0.50-0.81 Chromium and 0.44-0.65 Molybdenum. Bearing minimum tensile strength of 380 Mpa ASTM A335 Pipe have a minimum yield strength of 205 Mpa.

The composition chrome moly alloy steel pipe make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

Characteristics:

- Strong resistance to rupturing at high temperatures and high pressures

- May be used for Hydrogen Sulfide Corrosion Services

- Resistant to cracking from hydrogen attack and embrittlement

- Resistant to hot sulfide corrosion cracking

- Can be used for NACE Applications where sour environments are under high temp and pressure

- Can be used in NACE-MRO 175 Sour Service

- Ideal for creep rupture applications

- Can handle high temperatures with very low elasticity

Chemical Composition:

|

Grade |

UN |

C≤ |

Mn |

P≤ |

S≤ |

Si≤ |

Cr |

Mo |

|

Sequiv. |

||||||||

|

P1 |

K11522 |

0.10~0.20 |

0.30~0.80 |

0.025 |

0.025 |

0.10~0.50 |

– |

0.44~0.65 |

|

P2 |

K11547 |

0.10~0.20 |

0.30~0.61 |

0.025 |

0.025 |

0.10~0.30 |

0.50~0.81 |

0.44~0.65 |

|

P5 |

K41545 |

0.15 |

0.30~0.60 |

0.025 |

0.025 |

0.5 |

4.00~6.00 |

0.44~0.65 |

|

P5b |

K51545 |

0.15 |

0.30~0.60 |

0.025 |

0.025 |

1.00~2.00 |

4.00~6.00 |

0.44~0.65 |

|

P5c |

K41245 |

0.12 |

0.30~0.60 |

0.025 |

0.025 |

0.5 |

4.00~6.00 |

0.44~0.65 |

|

P9 |

S50400 |

0.15 |

0.30~0.60 |

0.025 |

0.025 |

0.50~1.00 |

8.00~10.00 |

0.44~0.65 |

|

P11 |

K11597 |

0.05~0.15 |

0.30~0.61 |

0.025 |

0.025 |

0.50~1.00 |

1.00~1.50 |

0.44~0.65 |

|

P12 |

K11562 |

0.05~0.15 |

0.30~0.60 |

0.025 |

0.025 |

0.5 |

0.80~1.25 |

0.44~0.65 |

|

P15 |

K11578 |

0.05~0.15 |

0.30~0.60 |

0.025 |

0.025 |

1.15~1.65 |

– |

0.44~0.65 |

|

P21 |

K31545 |

0.05~0.15 |

0.30~0.60 |

0.025 |

0.025 |

0.5 |

2.65~3.35 |

0.80~1.60 |

|

P22 |

K21590 |

0.05~0.15 |

0.30~0.60 |

0.025 |

0.025 |

0.5 |

1.90~2.60 |

0.87~1.13 |

|

P91 |

K91560 |

0.08~0.12 |

0.30~0.60 |

0.02 |

0.01 |

0.20~0.50 |

8.00~9.50 |

0.85~1.05 |

|

P92 |

K92460 |

0.07~0.13 |

0.30~0.60 |

0.02 |

0.01 |

0.5 |

8.50~9.50 |

0.30~0.60 |

Tensile Requirements:

|

Tensile Strength, min., psi |

P-5 |

P-9 |

P-11 |

P-22 |

P-91 |

|

ksi |

60 |

60 |

60 |

60 |

85 |

|

MPa |

415 |

415 |

415 |

415 |

585 |

|

Yield Strength, min., psi |

|

|

|

|

|

|

ksi |

30 |

30 |

30 |

30 |

60 |

|

MPa |

205 |

205 |

205 |

205 |

415 |

Note: P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

Mechanical Properties:

|

Mechanical properties |

P1,P2 |

P12 |

P23 |

P91 |

P92,P11 |

P122 |

|

Tensile strength |

380 |

415 |

510 |

585 |

620 |

620 |

|

Yield strength |

205 |

220 |

400 |

415 |

440 |

400 |

Heat Treatment Requirements:

|

Grade |

Heat Treatment Type |

Normalizing Temperature Range F [C] |

Subcritical Annealing or Tempering |

|

P5, P9, P11, and P22 |

Temperature Range F [C] |

||

|

A335 P5 (b,c) |

Full or Isothermal Anneal |

|

|

|

|

Normalize and Temper |

***** |

1250 [675] |

|

|

Subcritical Anneal (P5c only) |

***** |

1325 – 1375 [715 - 745] |

|

A335 P9 |

Full or Isothermal Anneal |

|

|

|

|

Normalize and Temper |

***** |

1250 [675] |

|

A335 P11 |

Full or Isothermal Anneal |

|

|

|

|

Normalize and Temper |

***** |

1200 [650] |

|

A335 P22 |

Full or Isothermal Anneal |

|

|

|

|

Normalize and Temper |

***** |

1250 [675] |

|

A335 P91 |

Normalize and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

|

|

Quench and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

Process

2. P2 And P12 Grade Steel. These Two Grades Of Steel Should Be Manufactured Using The Coarse Grain Melting Process.

Language

Language